LHM-1 over an ice covered fjord on Baffin Island with Davis Strait in the back.

Image: Lockheed-Martin

Written for Skies Magazine – November/December 2016

Suzanne was in desperate need of a follow-up MRI. Last time, she’d had to endure multiple flights and an all-day trip from her Nunavut village to Montreal for her scan. But today, she and her neighbours watched in awe as a massive, brilliant white hybrid airship slowly approached her village’s frozen harbour.

The airship touched down gently on its air-cushion landing gear, stopping right by the shore. This afternoon, the medical professionals in the airship’s fully-equipped imaging clinic would welcome Suzanne for her MRI appointment, steps from her home.

This isn’t science fiction. In just a few years, hybrid airships could be providing services like this to Canada’s North, helping to solve decades-long infrastructure challenges. With the ability to fly from point-to-point and needing minimal ground handling, hybrid airships can operate in ways other forms of transportation would find impossible.

“The biggest problem we have in the Canadian Arctic is transportation. It limits the economy. It limits growth, and it limits the opportunities for the people there,” said Dr. Grant Cool during an interview with ***Skies***. Cool is chief operating officer of Hybrid Enterprises, the exclusive worldwide reseller of Lockheed Martin’s LHM-1 hybrid airship.

“I grew up there and lived in those communities,” said Cool, who now resides in Edmonton. “They’ve been working for years to get all-season roads to go to communities and to the mines. And besides the environmental impact issues, the real reason they don’t have them is because the economy isn’t big enough.

“But for a moment, use your imagination and put a number of hybrid airships into a place like Yellowknife, and then use them to expand the economy. They go every day, they move constantly, they’re reliable, with trips to every community, to every project, to every mine site—they’re there all the time,” said Cool.

“We call them ‘ferry boats of the sky.’”

Refined design

Hybrid airships have been in development for decades, as engineers looked at ways of making them into a useful mode of transportation. The biggest problem to solve was ground handling, with the goal of reducing the platoon of people and ground support equipment needed to corral conventional airships and blimps.

It took a shift in perspective to solve the problem. “What had struck some of the designers was that they were going at this backwards,” explained Cool. So instead of trying to modify a lighter-than-air vehicle, “they said, ‘OK, let’s start with something really heavy and try to turn it into an airship.’”

Where a traditional airship operates around neutral, or perhaps a hundred kilograms heavy, the LHM-1 will operate up to 6,000 kilograms (six tonnes) heavy. “It’s the difference between a building and a tent—this is not going to move around in the wind,” said Cool.

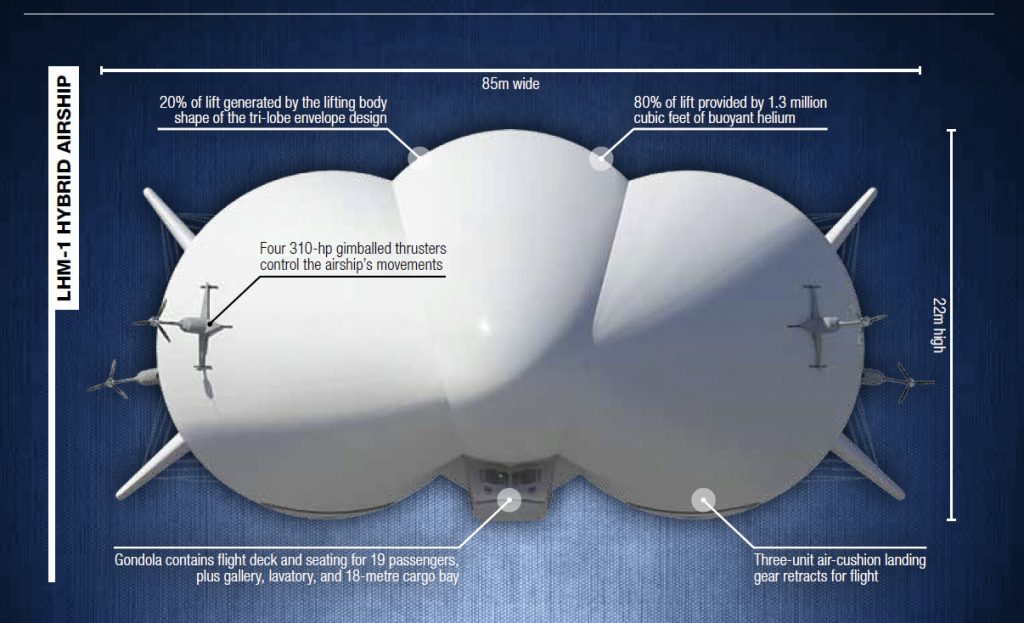

The LHM-1 is huge, measuring 85 metres long, 45 metres wide and 22 metres high. Its three-lobe envelope holds 1.3 million cubic feet of helium, which provides 80 per cent of the lift for the 40,000 kilogram gross weight airship.

The remaining 20 per cent of required lift is generated by a combination of the airflow around the aerodynamic lifting-body envelope and four gimballed thrusters. Each thruster is powered by a 310-horsepower diesel engine, and can swivel from up to down or full forward to reverse in a matter of seconds.

The final element needed to complete the design was the landing gear. To give the hybrid airship operational flexibility, a low pressure air-cushion landing system was developed. The LMH-1’s three-unit gear operates like a hovercraft, with the skirt folding up into an enclosed bay for flight.

With the combination of hybrid lift, thrusters, and air-cushion gear, the LMH-1 can operate from unimproved landing zones, on ice, or on water. It only needs a 150 metre area for a vertical takeoff or landing, and a 730 metre field for gross weight operations.

The LHM-1 can carry up to 21,000 kilograms (21 tonnes) of payload in its 18 x 3.2 by 3 metre cargo bay, along with up to 19 passengers in the forward section of the gondola. Cruising at a leisurely 60 knots at 2,000 feet, the hybrid airship has a 1,400 nautical mile range. Reducing speed will dramatically increase the airship’s range and endurance.

“It’ll fly 21,000 miles at 30 to 40 knots, for some 20 days,” explained Cool.

He stressed that the environmental impact and carbon emissions of the LMH-1 will be significantly less than existing aircraft. “Of course it’s going to be burning fuel, but we’re using a small fraction compared to fixed-wing and rotary-wing [aircraft],” he said.

And noise? “From 2,000 feet, you’ll barely hear this thing. The props are slow-speed, subsonic all the time.”

Pilots will control the LHM-1 with a joystick and throttle that’s connected to a sophisticated, F-35-derived flight control system. “There are too many variables going on for a pilot to directly control,” said Cool. “When you’re flying it, you’re just telling the computer what to do.”

In a class of its own

The pilots flying the LHM-1 will need a new licence for this class of air vehicle.

“There was no methodology for certifying this type of aircraft,” said Cool. “Fixed-wing, rotary-wing and lighter-than-air exist, so we had to create a brand new class of aircraft, called hybrid aircraft. We had to write all the rules and get Transport Canada and the FAA to accept them. That was done through 2013 and 2014.”

Straightline Aviation will be the first operator of the LMH-1, with an order for 12 of the $40 million hybrid airships. Based in the U.K., the company was founded by a team of former Virgin Lightship executives, all with extensive airship operational experience.

“We’re discussing the LMH-1 with potential customers all over the world,” said Straightline co-founder and COO, Mark Dorey. “One thing we’re not short of is interest from customers and end users for a variety of applications. Northern Canada and Alaska are two areas we’re looking at very closely.”

Straightline recently formed a strategic partnership with PRL Logistics Inc., a remote site logistics specialist based in Anchorage, to deploy the LMH-1 in Alaska. And, in an initiative reminiscent of the Orbis flying eye hospital, Straightline has signed an agreement with RAD-AID International, to deliver advanced radiology health services and medical imaging equipment to remote and underserved populations.

“There’s a lot of things we can do with the hybrid that others can’t,” said Dorey. “Beyond the customer base in mining and oil and gas, there are a lot of benefits that we can bring to remote populations. We can bring medical services, food and supplies, and fuel out to those regions, to reduce the cost of those essential items. And we can bring people and their products to market, as well.”

Comparing the operating costs of the LMH-1 to conventional aircraft is difficult, explained Cool, because hybrid airships don’t require airports and related ground infrastructure. “But on a per tonne basis there are no aircraft that can compare,” he said. “Twenty years from now, there could be airships landing right beside a factory that fly directly to a distribution centre.”

The first LMH-1 is under construction with flight tests targeted for 2018 and a planned entry-into-service in early 2019. Cool said the program is most of the way through certification in both Canada and the U.S. Much of the technology has already been developed and de-risked by Lockheed Martin, through test flights of the smaller P-791 experimental hybrid airship, starting 10 years ago.

So in just a few years, hybrid airships could be playing an integral role in Canada’s transportation infrastructure.

“Think of a truck-sized cargo in Yellowknife that has to go another 500 or 1,000 miles past the ‘end of the road.’ You just put it in the LMH-1 and take it there,” concluded Cool.

“Our motto is ‘No roads? No problem!’”