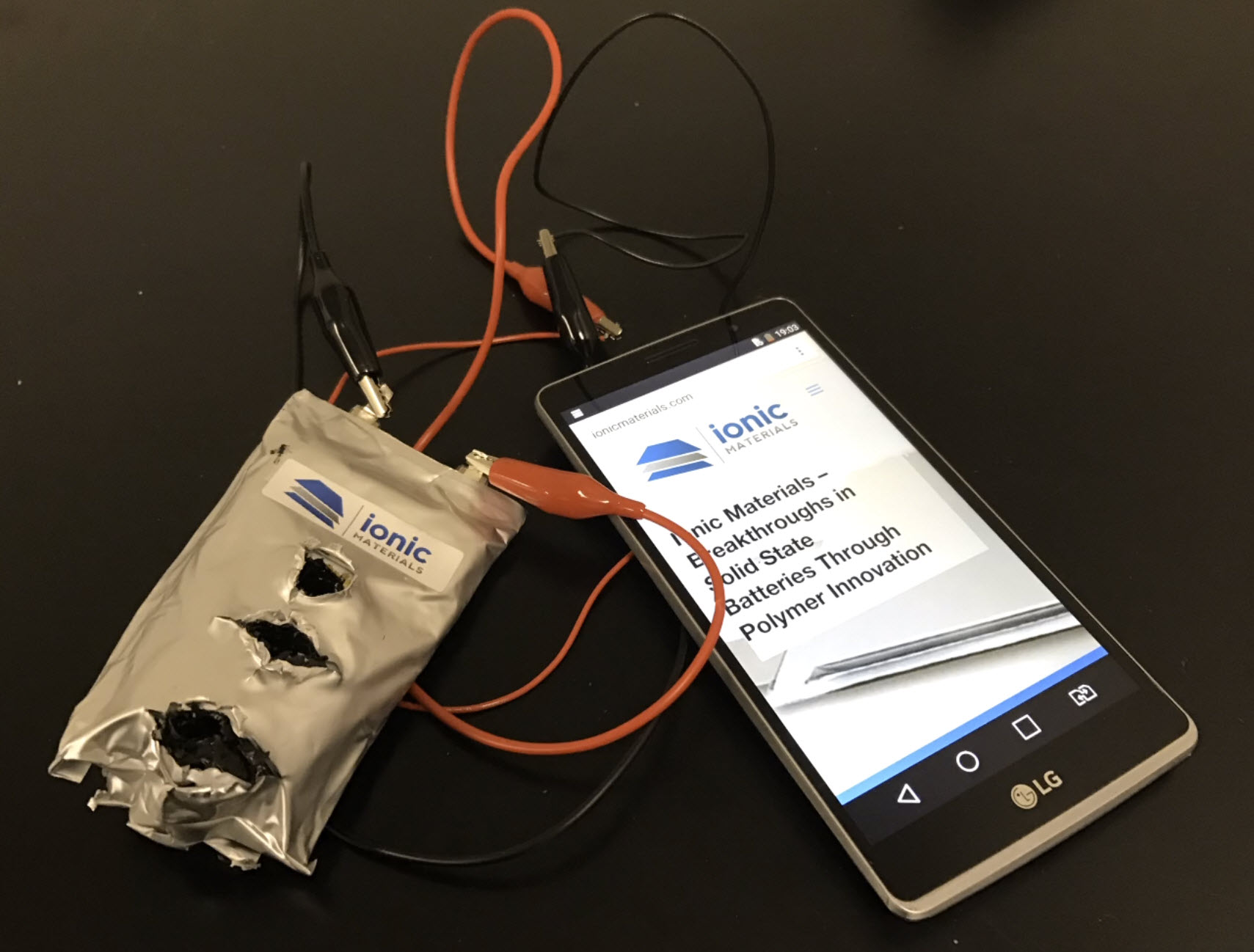

An Ionic Materials Li-Ion battery pack, full of bullet holes, still safely provides power to a device. Photo: Ionic Materials

Written for the APEX Experience magazine – Issue 8.2 – April-May 2018

Lithium-ion batteries are ubiquitous portable powerhouses in the world of rechargeable energy storage, with billions of cells produced annually. Found in everything from wireless earbuds to in-flight entertainment tablets, their pervasiveness extends to the aircraft cabin – but maybe not for long.

A Li-ion cell has a liquid electrolyte that saturates the battery’s key components, but is highly flammable. If a Li-ion cell is physically damaged, or if a battery’s charging circuitry malfunctions, the cell can become a raging inferno, spewing molten material with temperatures up to 1,985 degrees Fahrenheit – a thermal runaway that can destroy equipment and injure people.

The safety risks associated with the use of Li-ion batteries have been known since Sony introduced the first one in 1991, with the Federal Aviation Administration (FAA) reporting 160 air or airport incidents involving Li-ion batteries from that point to mid-2017. The issue gained widespread attention in 2016, when Samsung announced a global recall on its Galaxy Note 7 after reports that the smartphone was self-combusting on the ground and in the air.

The threat of thermal runaway in batteries has since led to a controversial US electronics ban, the Airline Passenger Experience Association’s subsequent call for solutions to the ban and, as of February, decisions made by Delta, American, Alaska, Southwest and Hawaiian airlines to prohibit baggage with non-removable Li-ion batteries.

“There is enough known about lithium-ion batteries to acknowledge that in the current architecture, they are a risk in an airplane,” says Erik Terjesen, senior director, Licensing and Strategy, Ionic Materials.

To solve the problem of thermal runaway, Ionic Materials has developed a unique polymer material – a solid plastic – that would entirely replace the liquid electrolyte in the battery. “You basically create a battery that is entirely solid, with no liquid component, that is non-flammable,” Terjesen says.

Ionic has tested the newly configured batteries to destruction, cutting cells in half, and firing bullets into the battery packs. Not only are the batteries stable, with no resulting explosions or fires, remarkably, the cells continue to provide power.

A next-generation “lithium-metal” battery using Ionic’s polymer could have roughly two to three times the energy density of a current Li-ion cell. And thanks to the polymer, even decades-old alkaline battery technology could see a reboot, becoming a rechargeable and inexpensive alternative to Li-ion cells. According to Terjesen, we could see safe and even more powerful batteries in the next few years.

“We’ve been in dialogue with people at the FAA and others – airlines and aviation players – and I think there’s the same view: If we can provide an inherently safe technology, that’s going to bring a lot more comfort,” Terjesen says.